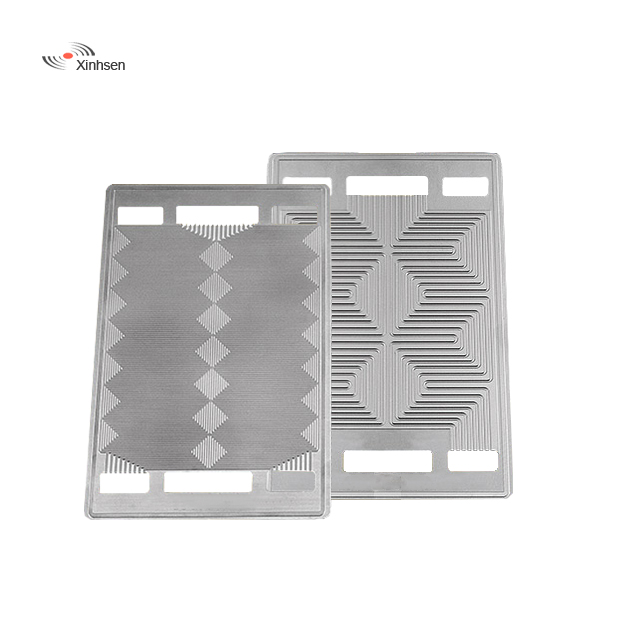

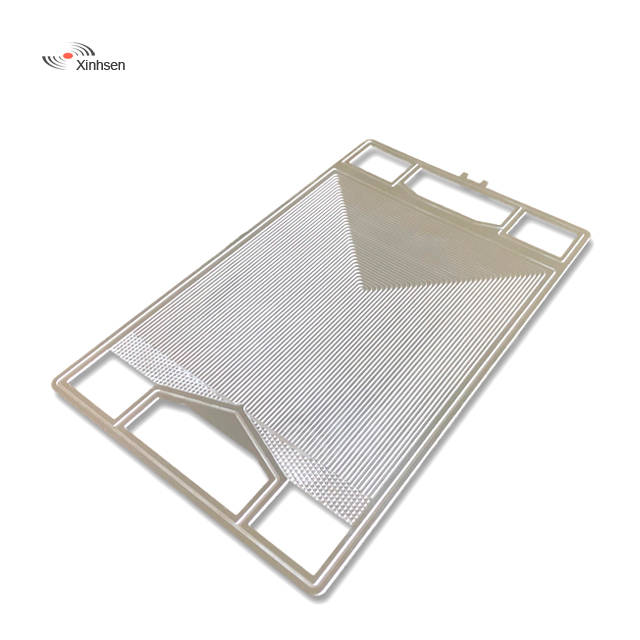

Printed circuit heat exchangers

Specialize in manufacturing metallic bipolar plate for hydrogen fuel cells and electrolysers.

Why choose Hysen?

Hysen has proven and advanced techniques in photo-chemical etching and diffusion bonding fields. We can offer a most cost-effective solution to our partners.

What’s PCHE

PCHE (Printed circuit heat exchanger) is a weldability, corrosion resistance and plate-type heat exchanger, mainly used in oil and gas industries.

A PCHE is manufactured from several corrosion resistance plates that are joined together by diffusion bonding technology.

Benefits of Photo-Chemical Etching

Burr-Free

Unlike traditional mechanical processing, etching does not produce burrs, ensuring that the component surfaces are smooth and flat, thereby enhancing the quality and performance of the components.

Long Lifespan

Due to the high precision, smooth surfaces, and stress-free nature of etched components, they generally have a longer lifespan.

Flexibility in Design/Customization:

Etching processing allows for the realization of complex and intricate designs, greatly enhancing the flexibility in component design and customization, and enabling quick responses to specific customer requirements.

No High Mold Costs

Etching processing does not require the creation of expensive molds, significantly reducing initial investment costs. This makes it particularly suitable for small batch production and rapid prototyping.