Custom Metal Photo Etching Products Machining

Photo Etching Products

Photo etching processing is a method of manufacturing precision parts by gradually dissolving and removing material from the surface using chemical etchants. Etching can be used to manufacture various products, some of which include:

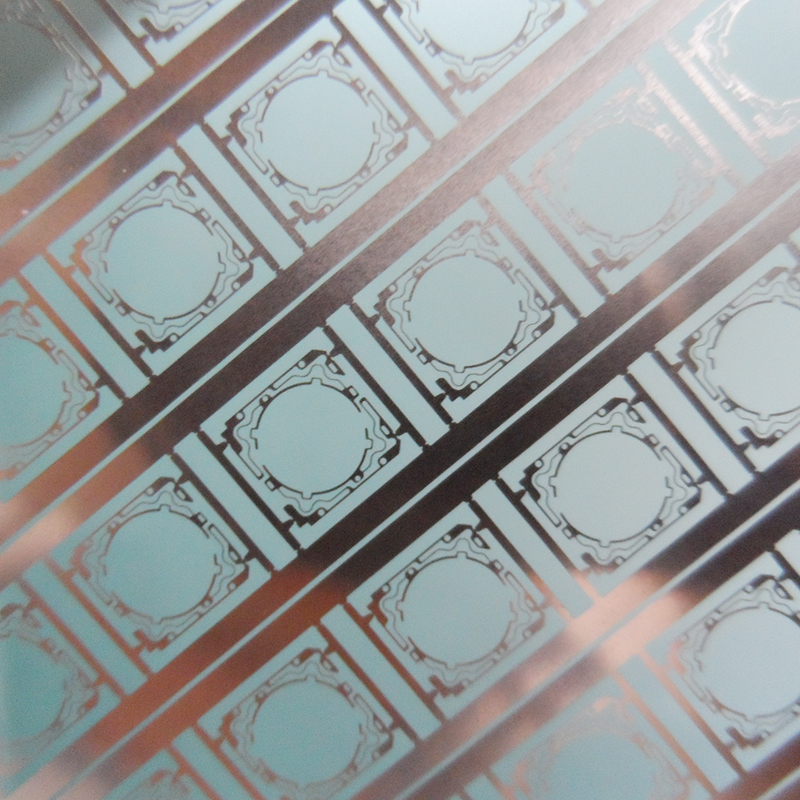

Printed Circuit Boards (PCBs): Etching can be used to manufacture PCBs by applying chemical etchants to remove unwanted portions of the copper layer on a substrate, forming circuit connections and traces.

Microelectronic Devices: Manufacturing microelectronic devices often requires precise processing techniques. Etching can be used to fabricate microelectronic components.

Microelectromechanical Systems (MEMS): Etching technology can be employed to manufacture tiny components in MEMS.

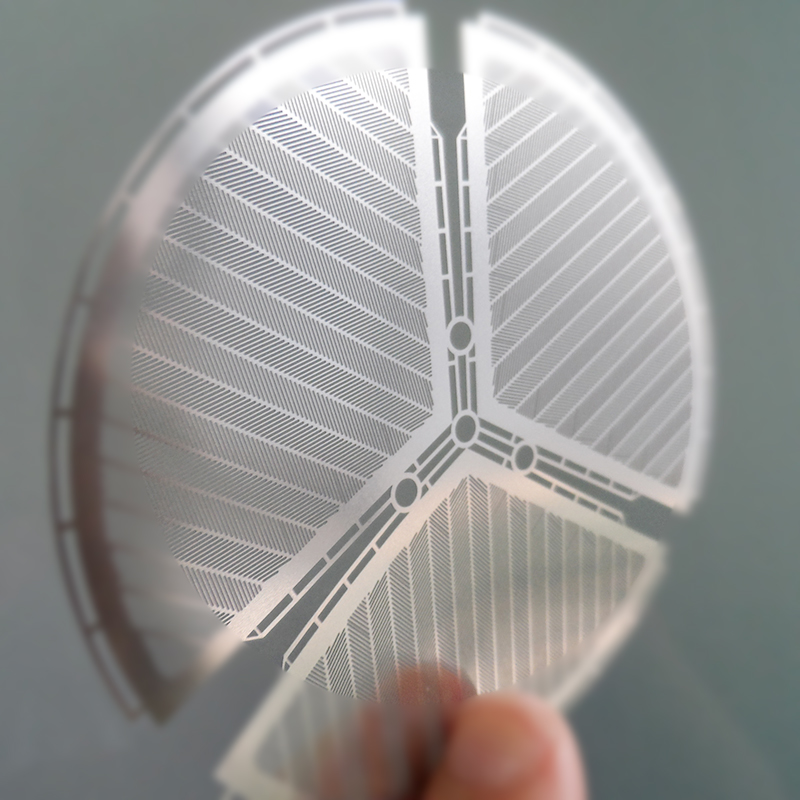

Microfluidic Devices: Etching processing can be used to fabricate microchannels and microreactors for microfluidic devices used in biomedical, chemical analysis, laboratory research, and beauty centers.

Molds and Models: Etching can be used to manufacture precision molds and models, such as microgears.

Ornaments and Artworks: Etching processing can be utilized in creating ornaments and artworks.

Filter Screens: Various micro-mesh screens, micro-perforated filter screens.

For example: microchips, IC semiconductor lead frames, sensors, encoders,speaker grills,microneedling for beauty, circuit heat exchanger, steel sheets for mobile folding screens, precision gaskets, VC heating plates, VCM shims, bipolar plates for hydrogen fuel cells, instrument panels, mobile reinforcement plates, electronic cigarette inner support frames, laboratory sieves, blow dryer screens, shower head, microvalves, micropumps, and microgears, molds and sculptures, metal crafts, jewelry, and decorative items, etc.

In summary, etching processing can be used to manufacture various precision metal parts and components, with applications spanning across electronics, automotive, aerospace, micromechanics, medical, biological, chemical, artistic, and other fields.

Custom Solutions of Photo Etching Prodcts

Photo Chemical Etching is a precise, cost-effective manufacturing process used to produce complex metal components with tight tolerances. At Hysenetch, we specialize in photo-chemical etching for a wide range of materials, including stainless steel, copper, titanium, nickel and various alloys.

By Photo Etching, we can offer customized and cost-effective metal photo etching products with the range of thicknesses from 0.01mm to 2.5mm, thus enabling the production of ultra-thin gaskets, which is useful in applications requiring support or isolation in limited space.

Our Typical Photo Etching Products

Need Help with High-Precision Metal Photo Etching Products Solutions? We Are Experts!

Click here to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.